Supply Chain Management –

Warehouse Management under SAP S/4HANA

Well-organized and efficient warehousing is essential for a state-of-the-art supply chain management. In particular, skills shortage and increasingly shorter lead times while maintaining high delivery reliability significantly challenge warehouse logistics. State-of-the-art warehouse management solutions optimize intralogistics processes and support them with a wide range of functions.

Warehouse Management Systems for Efficient Logistics Management

Warehouse Management Systems are the core of the logistics management and crucial for many supply chains: They help to manage stock levels physically as well as to control and monitor warehouse processes.

Warehouse management system requirements have increased in recent years: logistics are supposed to work quickly, efficiently and precisely. But at the same time, their goal is to remain flexible and to consider specific customer demands.

In order to meet these manifold challenges in the Supply Chain Management, SAP has developed trendsetting warehouse management solutions. These solutions virtually map the real-life warehouse conditions in a highly effective system.

The systems support the following requirements:

1. Maximum stock transparency:

A warehouse management system provides real-time insight into current stock levels and the movements of each individual material. The system identifies at all times where which material is located and what the workload in the warehouse is.

2. Lean processes and reduced walking distances:

A well-organized warehouse management system optimizes the degree of utilization of storage locations and minimizes unnecessary walking distances during order picking. This reduces costs and increases productivity.

3. Active control of movements

Modern warehouse management solutions allow the active control of movements in the warehouse. This optimizes the material flow, ensures smooth warehouse processes and supports employees in their daily work.

4. Connection of automated systems:

Whether an automated high-bay warehouse, a fast container conveyor technology, or a space-saving vertical lift system – all systems are managed centrally by the warehouse management system to ensure a seamless integration into the warehouse technology.

5. Mastering the challenges of modern logistics:

The skills shortage is confronting logistics with ever-growing challenges, while requirements are becoming increasingly complex. Efficient warehouse management systems can maintain pace and delivery capability and ensure effective inventory management despite scarce personnel resources.

SAP Warehouse Management Systems

Stock Room Management: interim solution for existing customers

SAP Stock Room Management (StRM) is a warehouse management solution integrated into SAP S/4HANA. From a licensing perspective, it is a new name for the previous SAP Warehouse Management (WM) and is based on the same tables, data structures, user exits and transactions as the previous WM. It has, however, fewer functions. StRM is included in the SAP S/4HANA license and is part of SAP’s release and maintenance strategy.

StRM primarily aims at existing customers operating simple, manually managed WM warehouses without any major process changes planned for the future. StRM provides companies with a simple and cost-effective way of transferring existing WM functions to SAP S/4HANA without the need to go through an extensive migration process.

If you compare WM to StRM, StRM does no longer support the following functionalities:

- Connection of subsystems via LSR interface (IDoc WMTORD/WMTOCO)

- Value Added Services

- Task Resource Management

- Cross Docking

- Yard Management

- Wave management

- Possibility to use Stock Room Management as a decentralized variant

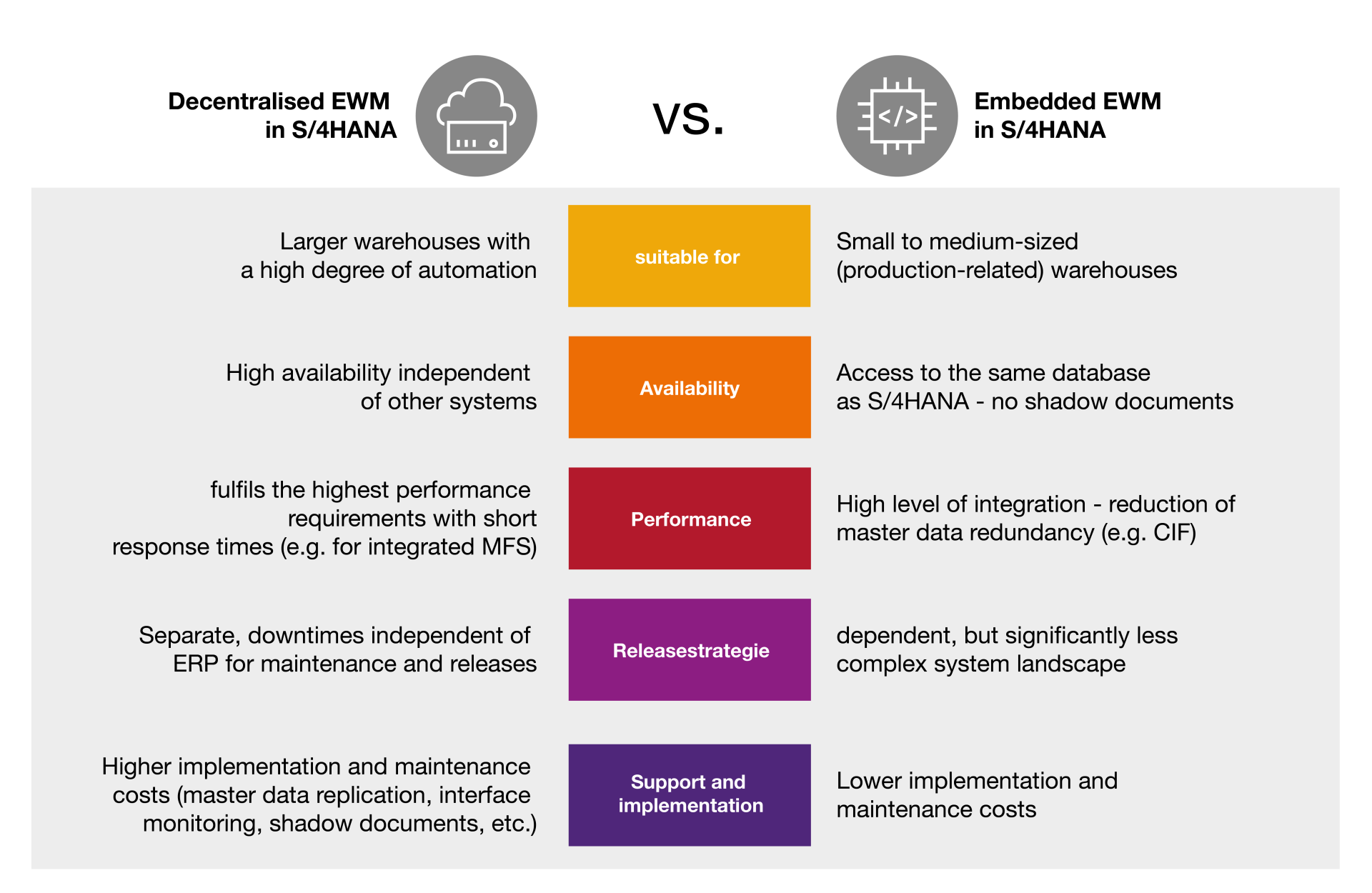

Decentralized EWM versus embedded EWM

EWM is available both as embedded EWM, which has been integrated into SAP S/4HANA, and as decentralized EWM, which runs independently of the ERP system on a separate instance. Both options have advantages and disadvantages.

The decision between a decentralized and embedded EWM depends on the specific requirements of a company. If you operate a large warehouse with a high degree of automation and want an independent release strategy, a decentralized EWM might be the better choice. For small to medium-sized warehouses with a focus on a high level of integration, for example with production, an embedded EWM is a suitable option.

Stock Room Management: interim solution for existing customers

SAP Stock Room Management (StRM) is a warehouse management solution integrated into SAP S/4HANA. From a licensing perspective, it is a new name for the previous SAP Warehouse Management (WM) and is based on the same tables, data structures, user exits and transactions as the previous WM. It has, however, fewer functions. StRM is included in the SAP S/4HANA license and is part of SAP’s release and maintenance strategy.

StRM primarily aims at existing customers operating simple, manually managed WM warehouses without any major process changes planned for the future. StRM provides companies with a simple and cost-effective way of transferring existing WM functions to SAP S/4HANA without the need to go through an extensive migration process.

If you compare WM to StRM, StRM does no longer support the following functionalities:

- Connection of subsystems via LSR interface (IDoc WMTORD/WMTOCO)

- Value Added Services

- Task Resource Management

- Cross Docking

- Yard Management

- Wave management

- Possibility to use Stock Room Management as a decentralized variant

Warehouse Management under SAP SAP S/4HANA – only with EWM?

The previous standard solution LE-WM for warehouse management in SAP ERP is no longer part of the SAP S/4HANA target architecture and will only be available in the so-called compatibility mode until December 31, 2025. After this date, it will no longer be accessible and must be replaced by a different solution.

There is no general answer as to which solution is the right one, EWM or StRM. StRM is only recommended for simple warehouses that are already operated with an SAP WM and that do not require any of the extended functions described above.

However, if you have not used a warehouse management system so far or if you want to modernize and expand your warehouse processes, StRM is not an option.

If you want to implement a new or improved warehouse management in SAP S/4HANA, EWM is the better choice – a more advanced and integrated solution for warehouse management in SAP S/4HANA.

Process Integration

Integrate production and warehouse processes

Warehouse management plays a crucial role in production logistics. Its task is to provide production with the right materials in the required quantity at the right time. It also has to meet increasingly complex requirements, such as end-to-end batch tracking and tracing or seamless integration into quality assurance processes.

Documenting incoming goods and feedback from production is an ideal example of a typical function at the interface between production and logistics: the data must be recorded as quickly and efficiently as possible – whether manually by the machine operator or automatically by a machine data recording system. As soon as the data has been recorded, the finished goods, which may be stored on pallets or packaged in some other way, must be taken immediately to the warehouse or the next production area.

Provide production with material

Production logistics is closely interlinked with manufacturing processes. The components required in production must be taken to the right workplace at the right time and in the right quantity. The detailed steps of this process can be complicated. Here are some examples of issues that can arise during this process:

- Is the material provided for a specific order or is it supposed to be available for all production orders?

- May only batches of specifically approved qualities be supplied for production orders?

- Is batch tracking and tracing relevant? Who or what determines which batch is required at the workplace?

- How do you deal with fluctuating material consumption if you want to keep the feedback processes as lean as possible?

- How do you integrate machine or production data acquisition into the process?

Incoming goods

As with production, a number of questions arise with regard to incoming goods:

- How do you register incoming goods as efficiently as possible on site?

- How do you label containers and pallets which you directly produce into?

- Quality management: How does the warehouse management provide support when quality assurance stocks are checked and moved?

- When products are packed in different packaging: Do you issue one material number or do you need various materials for different types of packaging?

consolut has gained in-depth experience in a large number of projects and in a wide range of industries – both in the implementation of SAP EWM and SAP WM/StRM. Our customers benefit from our holistic approach: warehouse and production specialists seamlessly collaborate.

Which solutions are suitable for connecting scanners?

Are additional Licenses for EWM unter SAP S/4HANA necessary?

You do not need any additional licenses to use the Extended Warehouse Management (EWM) under S/4HANA. A license for the EWM basic application is included in the SAP S/4HANA license; there will be no additional costs. The basic application includes all the basic functions required to operate a manual warehouse.

An Advanced license is required for additional functions. It entitles you to use additional functions such as the material flow computer (telegram control, conveyor technology), wave management and deconsolidation for incoming goods as well as transport units/gate management, cross docking, work management or value added services.

We would be happy to consult you in a workshop to determine which license options are suitable for your warehouse requirements and processes. We will help you find the ideal solution that meets your individual requirements without incurring unnecessary costs.

Your partner for your logistics project

Extensive experience

We have in-depth experience in consulting and implementing SAP solutions in various industries and are familiar with their challenges. This enables us to apply proven best practices to your individual project.

Wide experience with WM and EWM installations based on SAP S/4HANA

We have in-depth experience in the implementation of Warehouse Management (WM) and Extended Warehouse Management (EWM) under S/4HANA. We have successfully completed projects in various S/4HANA releases and are familiar with the latest technologies and functions.

Holistic approach

We examine your logistics processes from an end-to-end, holistic and integrative perspective. We do not just focus on implementing single solutions, but on optimizing your entire logistics processes with the goal of establishing seamless and efficient operations.

Consulting at eye level

Together with you, we develop customized concepts and solutions that we precisely tailor to your specific needs. We put your satisfaction and your project success first.

Combining process understanding and technical know-how in SAP

Our team combines in-depth understanding of processes with comprehensive technical expertise in the SAP environment. We know how to optimally map and automate your business processes in SAP and thus to increase your efficiency.

Our approach

The first and decisive step: we determine which solution is the right one for your company in a thorough analysis or in a joint workshop. Because every process is different.

Our experts develop tailor-made solutions to maximise your warehouse and logistics efficiency. They pave the way to greater competitiveness and success.

We not only specialise in warehouse management, but also cover the entire spectrum of business SAP knowledge – both finance and logistics. We contribute our many years of experience from projects at manufacturing companies in a wide range of industries.

We are glad to help.

Do you need support with supply chain management? Talk to us!